The best damn Technics 1200 under- platter LED kit

Here’s one post of what will likely be many regarding one of our many custom under-platter kits for the Technics SL-1200.

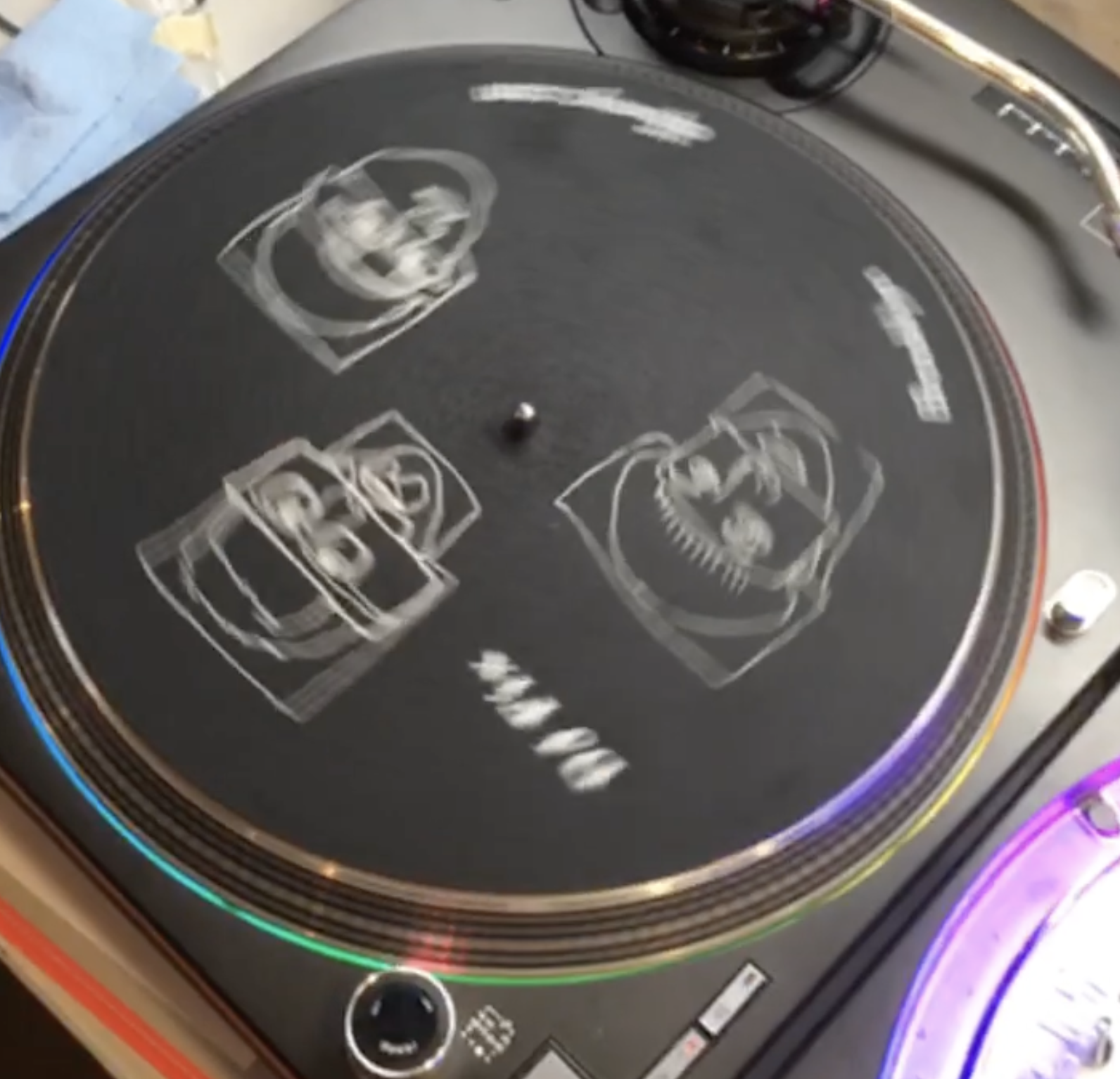

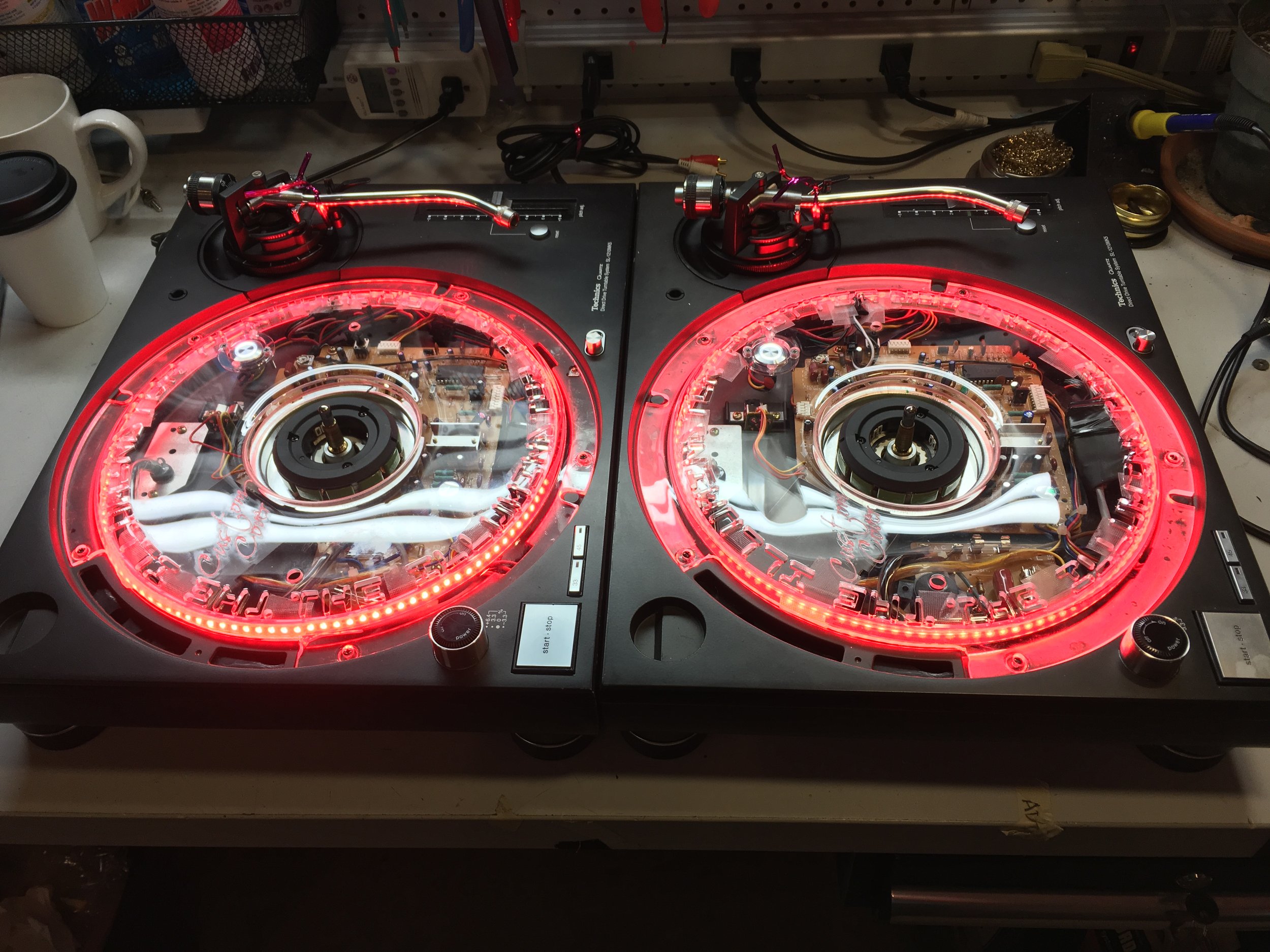

128 Neopixels! Here’s LED under-platter (AKA panel cover) kit Version 2. Programming was a mix of Neopixel FastLED library and DJ Fix custom work with help from Manx programmer and Accordionist Shane Kerwin.

You can see many of the programs: rainbow, solid, chase (with “fire” effect), and starry night, which is a deep blue background with “stars” appearing and disappearing.

A customer reached out to us a while back asking if we knew anything about an LED platter kit for tech 12s. For those who are unfamiliar: The idea is similar to the under-glow kit on a car, except we’re looking for light to shine out from underneath the platter. There are a few versions of this out there, but as we’ve seen at the shop, none are too good. We had repaired some LED platter kits which either blew out their power supplies or were installed in a way which caused a short circuit. There were some versions which—in an effort to make room for the LEDs—did away with the panel cover, which is the plastic piece covering the electronic guts inside the metal chassis. Eliminating the panel cover is a terrible idea, as it leaves all the important parts vulnerable to dust and damage. There were some designs in which someone had fabricated a clear panel cover—the right idea—but either the fitment was really bad, or the LED density was no good.

So we made our own! Our goal was to make an under-platter LED kit with the following specs:

It must be reliable.

It must be LED dense; producing lots of light with little to no breaks in the LED string, so that it looks smooth when animated.

It must be powered by its own power supply with protection in case of any shorts or other problems.

It must have interesting options in terms of the “light show” programmed into it; featuring many colors and animations.

It must be easy to use.

It must fit correctly, so that the turntable should be used as if it were factory.

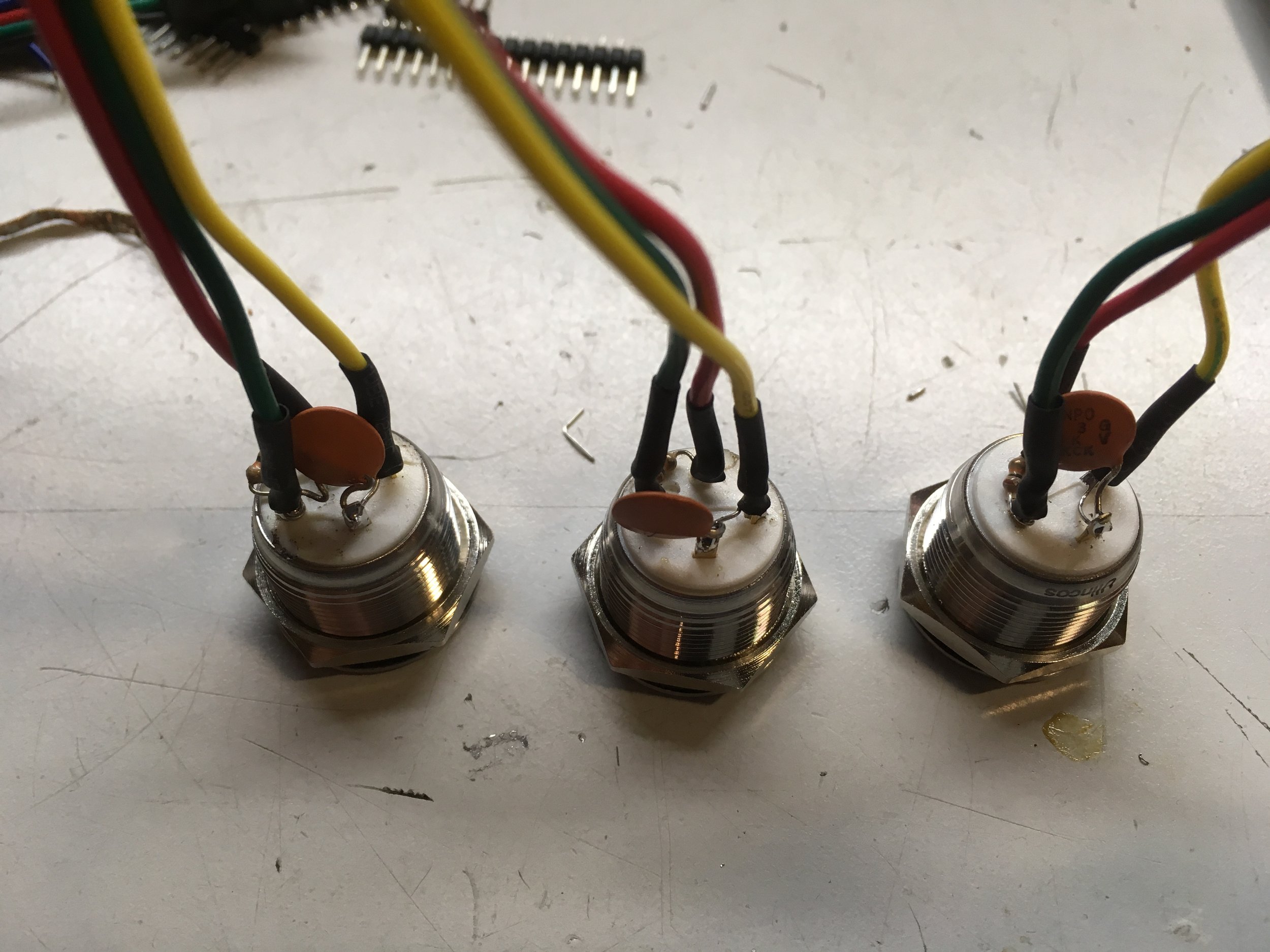

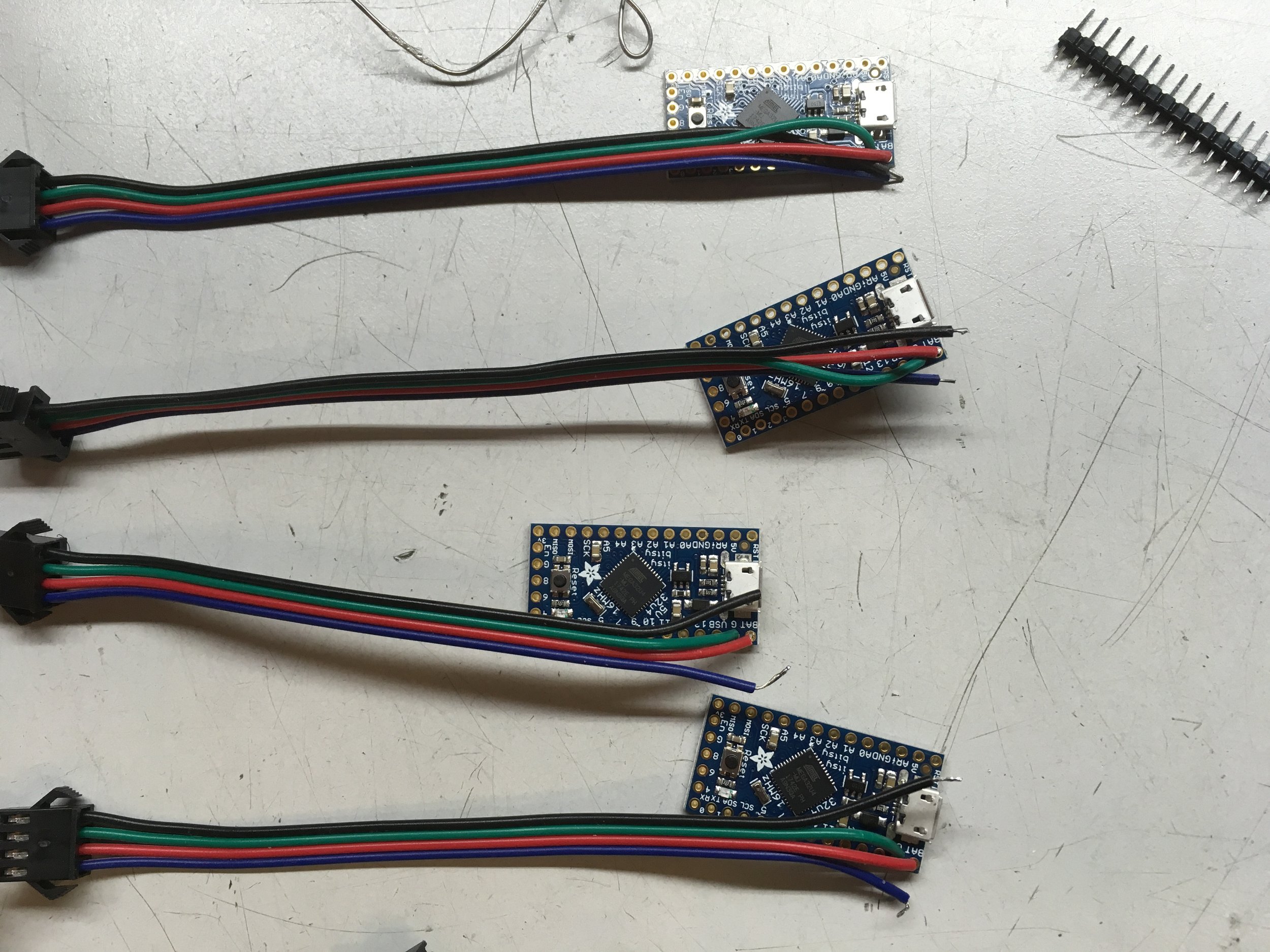

Although our design changed over time as we learned new tricks and adjusted for quirks with each iteration, the design goals remained the same. Here we see our second iteration, which included a cool lighted pushbutton which can be accessed through the holes on the platter. The first prototype (which will be its own blog-post) featured a custom house-made epoxy panel cover. We later moved to an aftermarket clear panel cover, which looked great. Finally, we got rid of the button and made the microcontroller remote controlled. Programming was Arduino-based, and power supply was a super efficient low-noise switching unit from MeanWell. Light density was fantastic, and could be seen even in relatively bright light. Some of these pictures show our pre-fab switch and power supply assemblies.

Finally, while these were a really fun challenge to make, it was tough to make money on them and we broke even, at best. Maybe one day we’ll have the budget to design a little mass-production infrastructure. Til then, they will remain a custom-order only, and the cost will reflect the bespoke quality of each unit.